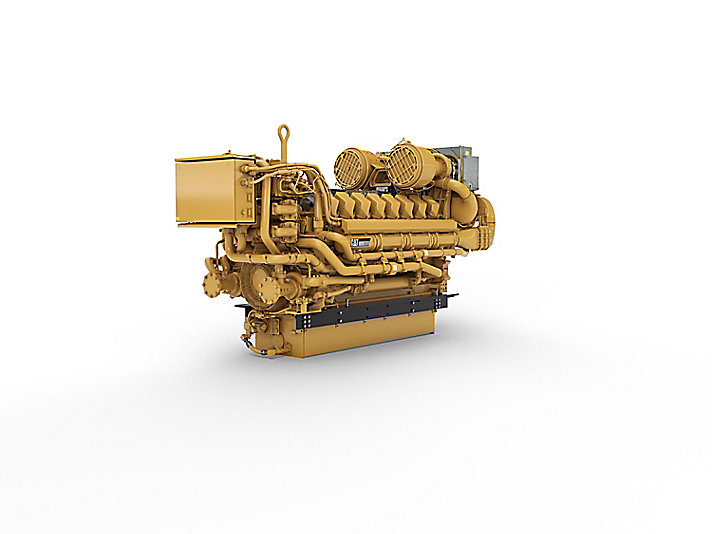

Động cơ thuỷ C175-16

Thông số kỹ thuật

| 2683-3420 bhp (2001-2550 bkW) |

| Tốc độ | 1600-1800 rpm |

| Tiêu chuẩn khí thải | IMO II |

| Kiểu nạp khí | TA |

| Đường kính | 175.0 mm |

| Hành trình píttông | 220.0 mm |

| Dung tích xylanh | 84.67 l |

| Chiều quay tính từ cuối bánh đà | Ngược chiều kim đồng hồ |

| Cấu hình | Vee 16, 4-Stroke-Cycle Diesel |

| Khối lượng | 13041.0 kg |

| Chiều cao | 2478.0 mm |

| Chiều dài | 4515.0 mm |

| Chiều rộng | 1845.0 mm |

Tính năng nổi bật & Lợi ích

Designed and sized to allow for greater power output in the future. Thermo-laminated heat shields save time and money during service

Wide range of available power ratings, Compliant with no aftertreatment required, Cat® durability

EPA Marine Tier 3/IMO Tier II Emissions Compliant, Common rail fuel system enables low emissions at all levels

Marine Classification Society approved monitoring, alarm, and protection system, Cross-flow head design optimizes fuel consumption

13% more power for increased productivity, Standard warranty on all factory-packaged components

This system features electronically controlled, fully flexible injectors, enabling optimal combustion and low emissions at all levels, along with better transient response.

Improved airflow helps the air/exhaust flow meet emissions and optimize fuel consumption

Allows for easy installation and maintenance, reducing up front and service costs.

Cast titanium impeller offers five times longer low-cycle fatigue life, and compressor blades are twice as resistant to high-cycle fatigue. Turbochargers are mounted on cast pedestals and center-positioned to eliminate external oil drain lines, reduce the chance of oil leaks, and improve turbo efficiency. The flexible bellows connections used on inlets/outlets of the turbine and compressor housings minimize leakage and provide isolation from external vibrations, motions, and thermal expansion.

Now offered as a factory-installed and warranted option, saving you money and providing a single source for the whole package.

Easier to install and remove than the traditional soft shields, they save time and money during service. The no-gap fitting enhances safety with better hot spot coverage.

Trang thiết bị

AIR INLET SYSTEM

- Air cleaner; 2 single element canisters

- Air cleaner mounting

CONTROL SYSTEM

- Caterpillar Dual ADEM A4 Electronic Engine Control, front mtd.Requires 24V DC 20 amp continuous, 40 amp intermittent, clean electrical power

COOLING SYSTEM

- Engine Configuration for Remote Cooling

EXHAUST SYSTEM

- Dry Exhaust Manifold and dual turbochargers with heat shields

FLYWHEELS & FLYWHEEL HOUSINGS

- Flywheel housing, SAE No. 00

- Flywheel, 530 M (SAE No. 21), 183 teeth

FUEL SYSTEM

- Fuel transfer pump, RH Fuel priming pump, RH Double walled high pressure fuel lines Electronically controlled unit injectors Leak detection Customer connections, RH Shipped loose duplex primary fuel filters with water separators Duplex secondary and ter

INSTRUMENTATION

- Features: Start/stop controls Emergency stop Terminal blocks for customer connections

- Switches: Cranking override-RH and LH Crank selection Low idle Prelube override

- Graphical Unit (Color Marine Power Display) for analog or digital of: Engine oil pressure, engine water temperature, fuel pressure, system DC voltage, air inlet restriction, LH & RH exhaust temperature (prior to turbocharger), fuel filter differential, oi

- Indication lights: Auxiliary one and two circuits Emergency stop lamp General alarm lamp Local speed control

LUBE SYSTEM

- Gear type lube oil pump Integral lube oil cooler Oil drain valves, FRONT Oil sampling valve Duplex oil filter Filler and dipstick Fumes disposal 1000 hour sump oil pan

PROTECTION SYSTEM

- A4 Electronic Monitoring System provides customer programmable engine derating strategies to protect against adverse operating conditions.

- Emergency stop push button (located in Electronic Instrument Panel) Safety shutoff protection: Oil pressure and water temperature(redundant OP and WT sensors) Overspeed (redundant and independent of engine governing system speed sensed by backup ECM whic

STARTING SYSTEM

- High and Low current power distribution box NOT INCLUDED: Starting motor

MARINE SOCIETY REQUIREMENTS

- See MARINE SOCIETY REQUIREMENTS optional attachments

GENERAL

- Vibration damper and guard Lifting eyes Paint, Caterpillar yellow engine with black rails. Preservation of cooling system, air intake and exhaust for one year indoor storage

IMO CERTIFICATION (EMISSIONS)

- For GL IMO certification for vessels with a German Flag, additional certificatio nthrough the German Authority SeeBG is required.

CHARGING SYSTEM

- Alternator Harness: 10M/32FT, 20M/64FT, 30M/98FT

- Battery Charger 20 AMP

COOLING SYSTEM

- Coolant Level Sensor

EXHAUST SYSTEM

- Flexible Fitting

- Flanges

- Flange & Exhaust Expanders

FUEL SYSTEM

- Flexible Fuel Lines

INSTRUMENTATION

- PL 1000E Communication Module

- Marine Gear Sensors

- Color Marine Power Display System

- Turbocharger Speed Sensors

LUBE SYSTEM

- Electric Prelube Harness

SPECIAL TESTS/REPORTS

- Special Test Charge – English Only

- STD Engine Test Charge

STARTING SYSTEM

- 24 Volt Battery Set – Dry (QTY6)

- Starter Motor Harness

SERVICE TOOLS/SHIP PROT./ FACTORY SUPPORT

- Shrink Wrap Protection

- Export Packaging