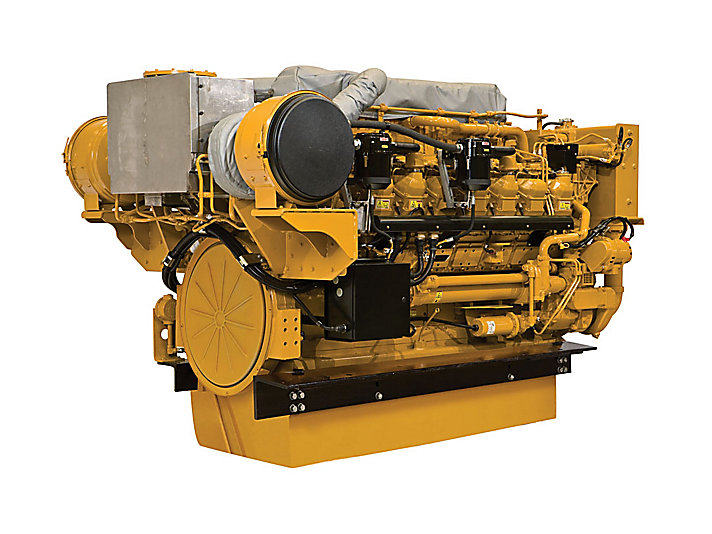

Động cơ máy thuỷ 3512C TIER 3

Động cơ đẩy CAT 3512C với dải công suất rộng và đáp ứng tiêu chuẩn khí thải EPA Marine Tier 3 và IMO II mà không phải hy sinh công suất. Các động cơ đẩy, động cơ phụ trợ và động cơ DEP được thiết kế và sản xuất dựa trên nền tảng 3512C và 3516C và đã giảm tổi thiểu kích thước và khối lượng. Chi phí sở hữu và vận hành cũng được giảm. Những đặc tính nổi bật mới bao gồm tấm chắn nhiệt bằng thép không gỉ, hệ thống các-te kín và đáp ứng tiêu chuẩn EPA Tier 3.

Thông số kỹ thuật

| 1340-2366 bhp (1000-1765 bkW) |

| Tốc độ | 1600-1800 rpm |

| Tiêu chuẩn khí thải | EPA Tier 3, IMO II |

| Kiểu nạp khí | TTA |

| Đường kính | 170.0 mm |

| Hành trình píttông | 215.0 mm |

| Dung tích xylanh | 58.6 l |

| Chiều quay tính từ cuối bánh đà | Tùy chọn Ngược chiều kim đồng hồ hoặc Cùng chiều kim đồng hồ |

| Cấu hình | Vee 12, 4-Stroke-Cycle Diesel |

| Khối lượng tối thiểu | 7488.0 kg |

| Chiều dài tối thiểu | 2465.0 mm |

| Chiều dài tối đa | 2465.0 mm |

| Chiều cao tối thiểu | 2222.6 mm |

| Chiều cao tối đa | 2222.6 mm |

| Chiều rộng tối thiểu | 2037.0 mm |

| Chiều rộng tối đa | 2037.0 mm |

Tính năng nổi bật & Lợi ích

Uses advanced predictive modeling software to select best nozzle configurations and combustion cylinder geometry, Stainless steel exhaust manifold and turbo heat shields, Closed crankcase ventilation system, Dual camshafts, Reduced aftercooler heat load for smaller heat exchanger requirements

A wide range of power ratings available, No aftertreatment technology required, Fuel consumption nominal rated BSFC

Modified piston bowl shape to improve combustion and reduce emissions, Uses K-factor injector to align with predictive model analysis, Better electronic injection control using crank timing vs. cam timing, EPA Marine Tier 3/IMO Tier II Emissions Compliant, Lower IMAT = Lower NOx

Electronic governing (A4 ECU), Instrument panel shipped loose with Color Marine Power Display (MPD), Cold mode start strategy, Programmable low idle, Optional marine alarm and protection system

Single-source support, Caterpillar warranty for all factory packaged components, Industry-leading one-year warranty on parts

Trang thiết bị

AIR INLET SYSTEM

- Separate circuit aftercooler core, corrosion resistant coated (air side)

- Powercore air cleaner

CONTROL SYSTEM

- Dual Caterpillar A4 Electronic Engine Control with Electronic Unit Injector Fuel System

- Rigid Wiring Harness (10 amp DC power required to drive Electronic Engine Control Module)

EXHAUST SYSTEM

- 3500C engines:

FUEL SYSTEM

- Fuel transfer pump

- Electronically Controlled Unit Injectors

LUBE SYSTEM

- Crankcase breather groups, Top mounted

- Oil filler and dipstick, LH or RH

- Oil pump, gear type

- 250 or 1000 hour sump oil pan

MOUNTING SYSTEM

- 3500C engines:

POWER TAKEOFFS

- Accessory drives: Lower RH, lower LH

- Front housing, two-sided

PROTECTION SYSTEM

- A4 Electronic Monitoring System provides customer programmable engine derating strategies to protect against adverse operating conditions

- Emergency stop push button (located in Electronic Instrument Panel)

- Safety shutoff protection:

GENERAL

- Vibration damper and guard

- Lifting eyes

- NOTE: Engines for heat exchanger cooling do NOT include heat exchange

FLYWHEEL AND FLYWHEEL HOUSING

- Flywheel, SAE No. 00, 183 teeth

- Flywheel housing, SAE No. 00

COOLING SYSTEM

- Oil cooler

- Thermostats and housing, Full open temperature 92 C (198 F)

- Jacket water pump, gear driven, centrifugal

- Auxiliary fresh water pump

- Aftercooler system: If using glycol, up to maximum 20% glycol concentration is allowed

INSTRUMENTATION

- Electronic service meter, instrument panel (24V), start/stop switch, emergency stop button, maintenance due light, diagnostic light, warning light, maintenance clear switch, start motor magnetic switch, 15 and 3A breakers

- Graphical Unit (Color Marine Power Display) for analog or digital of:

AIR INLET SYSTEM

- Air Inlet Adapters

CHARGING SYSTEM

- Battery Chargers

- Charging Alternator

CONTROL SYSTEM

- Throttle Control

COOLING SYSTEM

- Coolant Shunt Tank

- Cooling System Options

EXHAUST SYSTEM

- Flexible Fittings

- Elbows

- Flanges

- Flange and Exhaust Expanders

- Mufflers

FUEL SYSTEM

- Fuel Cooler Heat Exchanger – Sea Water

- Primary Fuel Filter

- Fuel Level Switch

- Rigid Fuel Lines

- Flexible Fuel Lines

INSTRUMENTATION

- Communication Modules

- Color Marine Power Display System

- Pilot House Instrument Panels

- Marine Gear Sensors

LUBE SYSTEM

- Sump Pumps

- Lubricating Oil

POWER TAKE-OFFS

- Stub Shafts

- Crankshaft Pulleys

- Damper Guard

- Flexible Coupling and Guards

MARINE SOCIETY REQUIREMENTS

- Green Passport Documentation

- Spray Shielding

PROTECTION SYSTEM

- Shutoff and Alarm Contactors

SPECIAL APPEARANCE PACKAGES

- Special Appearance Packages with Chrome Covers

- Yacht Class Finish

STARTING SYSTEM

- Air Starting Motor Options

- Battery Sets – 24 Volt – Dry

- Battery Rack

MOUNTING SYSTEM

- Engine Supports

- Vibration Isolation Mountings

PAINTS

- Paint Color Options

PACKING

- Shrink Wrap Protection

- Storage Preservation with Glycol Solution/Vapor Corrosion Inhibitor

- Export Boxing

- Export Packaging