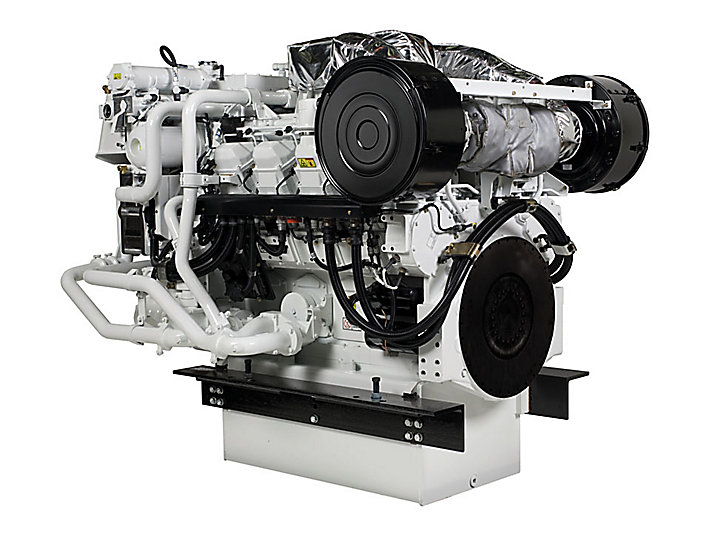

Động cơ máy thuỷ 3508C

Động cơ đẩy 3508C đáp ứng tiêu chuẩn khí thải IMO II. Hơn nữa, 3508C có hiệu quả sử dụng nhiên liệu và dầu bôi trơn vượt trội. Nền tảng động cơ đẩy 3500 là dòng sản phẩm dẫn đầu ngành công nghiệp và đã được chứng minh về sự hoạt động ổn định và bền bỉ.

Thông số kỹ thuật

| 775-1100 bhp (578-820 bkW) |

| Tốc độ | 1200-1600 rpm |

| Tiêu chuẩn khí thải | IMO II, EU IW |

| Kiểu nạp khí | TTA |

| Đường kính | 170.0 mm |

| Hành trình píttông | 190.0 mm |

| Dung tích xylanh | 34.5 l |

| Chiều quay tính từ cuối bánh đà | Tùy chọn Ngược chiều hoặc cùng chiều kim đồng hồ |

| Cấu hình | Vee 8, 4-Stroke-Cycle Diesel |

| Khối lượng tối thiểu | 4960.0 kg |

| Chiều dài | 2117.0 mm |

| Chiều cao | 1829.0 mm |

| Chiều rộng | 1703.0 mm |

Tính năng nổi bật & Lợi ích

• One of the most advanced electronic control systems available for Cat marine engines.

• Faster with more memory capability than ADEM 2

• Compatible with several optional display systems

• Does not require fuel cooling

• Enhanced input/output capacity

• Rugged marine design and IP66 connectors

• Award-winning circuitry design

• Integrated MPD display for quick response and effective local control

• Optional local speed control

• Optional individual cylinder exhaust temperature scanner with data link for remote mounting

• Local E-stop, warning indicators, horn

• Plug & Run connections allow mounting on port or starboard side of engine

• Graphic display of engine operating parameters in analog, digital, or bar-chart format

• Rugged weatherproof construction

• Fully user-configured display screens

• Marine classification society-type approved

• Diagnostic messages and alarms

• Three-tier prioritization of events and diagnostics

• Multilingual capability

• Night-mode LCD display

• ISO symbols for parameter identification

• Standard marine twin turbocharger configuration.

• More reserved power for superior part load performance at continuous ratings

• Turbos tuned for high power and excellent fuel consumption

• Separate Circuit Aftercooled (SCAC)

• Single heat exchanger for both jacket water and aftercooler systems

• Single inlet and outlet connections for sea water

• Lightweight and compact

• Factory-installed piping and connections

• Highly durable: long service life

• Flexibility for custom wire additions

• Lined with fire retardant foam

• Cost efficient replacement for premium wiring

• Marine classification society approved

• Isolates “control power” from alternator/starter/jacket water heater power

• Mountable off engine

• Allows end user to choose up to three independent power sources

• Has built-in circuit breakers and switches for easy troubleshooting

• ABS/DNV/LR/GL/CCS/BV/RINA

• 3D histogram data of engine operation (load, speed, time)

• Load feedback signal for CPP operation

• Electronic torque limit for re-power and torque limited application equipment

• Programmable droop

• Adjustable governor gains

• Condition-based maintenance

• Monitoring features

• Serial data bus communications

• Primary and secondary A3 controllers on all propulsion engines

• Cat pilot house panels with or without Marine Power Display (MPD)

• Easily connected to the engine customer connector

• Ability to have full function helm panels and reduced function wing panels

• Caterpillar designed and built system

• “Drop-in” installation

• No threaded fuel connections

• High pressure only inside injector does not require double wall lines or leak collection devices

• Power take-off adapters available

• Auxiliary drives for power take-offs for hydraulic pumps and compressors

• Standard engine-mounted aftercooler pump

• Standard engine-mounted jacket water pump

• Optional engine-mounted, gear-driven, high capacity sea water pump

• Rigid mounting points

• Optional resilient mounting

• Easily removable side covers

• Accessible bearing caps

Trang thiết bị

FUEL SYSTEM

- Fuel filter, RH, with service indicators.

- Fuel transfer pump.

- Electronically controlled init injectors

INSTRUMENTATION

- Graphical Unit (Marine Power Display) for analog or digital display of

LUBE SYSTEM

- Crankcase breather, Top mounted

- Oil filter, RH, with service indicators

- Oil filler and dipstick, RH

- Standard sump oil pan (500 Hour oil change interval)

- Oil pump, gear type

MOUNTING SYSTEM

- Rails, engine mounting, ledge type, 203 mm x 203 mm (8 in x 8 in)

POWER TAKEOFFS

- Accessory drive

- Front housing, two-sided

GENERAL

- Vibration damper and guard

- Lifting eyes

- Paint, Caterpillar Yellow engine with black rails

- NOTE: Engines for heat exchanger cooling do NOT include heat exchanger.

FLYWHEEL AND FLYWHEEL HOUSING

- Flywheel, SAE No. 0, 151 teeth.

- Flywheel housing, SAE No. 0.

AIR INLET SYSTEM

- Separate circuit aftercooler core, corrosion resistant coated (air side)

- Air cleaner, regular duty

- Dual turbochargers, 152 mm (6 in) OD straight connection

CONTROL SYSTEM

- Dual Caterpillar A-III Electronic Engine Control, LH with Electronic Unit Injector Fuel System

- Rigid Wiring Harness (10 amp DC power required to drive Electronic Engine Control Module)

COOLING SYSTEM

- Oil cooler

- Thermostats and housing, Full open temperature 92 C (198 F)

- Jacket water pump, gear driven, centrifugal

- Auxiliary fresh water pump with SCAC engines

- Auxiliary sea water pump, Centrifugal, Non-self-priming

- Expansion tank

EXHAUST SYSTEM

- Dry gas tight exhaust manifolds with heat shields.

- Dual turbochargers with watercooled bearings and heat shield.

- Exhaust outlet, vertical, 203 mm (8 in) round flanged.

PROTECTION SYSTEM

- A4 ECU Electronic Monitoring System provides customer programmable engine de-rate strategies to protect against adverse operating conditions

- AIII Electronic Monitoring System provides customer programmable engine de-ration strategies to protect against adverse operating conditions

- Emergency stop push button (located in Electronic Instrument Panel) Safety shutoff protection:

CHARGING SYSTEM

- Battery Charger, 10 amp

- Charging Alternators

COOLING SYSTEM

- Water Level Switch Gauge

- Coolant Level Sensors

- Connections

- Keel Cooling Conversions

- Heat Exchangers

- Auxiliary Water Pumps

- Sea Water Pump Removal

- Coolant Shunt Tanks

- Air Separator

- Marine Gear Cooling

INSTRUMENTATION

- PL1000T Communication Module

- Customer Interface

- Thermocouples

- Remote Panel Display

- Remote Cylinder Temperature Display

- Pilot House Instrument Panels

- Marine Gear Sensors

- Engine Vision Display System

MOUNTING SYSTEM

- Engine Supports

- Vibration Isolators

POWER TAKE-OFFS

- Front Housing Accessories

- Flexible Coupling and Guards

- Upper Left Hand Front Location:

- Upper Right Hand Front Location:

- Upper Right Hand Rear Location:

- Lower Left Hand Front Location:

- Lower Left Hand Rear Location:

- Front Housing Accessory Drives

- Upper LH Accessory Drive

- Upper RH Accessory Drive

- Front Power Take Offs

- Crankshaft Pulleys

- Damper Guard Removals

AIR INLET SYSTEM

- Remote Air Inlet Adapters

CONTROL SYSTEM

- Throttle Position Sensor

- Throttle Position Signal Conv.

- Throttle Position Sensor Removal

- Local Speed Throttle Control

- Throttle Synchronization

EXHAUST SYSTEM

- Exhaust Outlet

- Flexible Fittings

- Elbows

- Flanges

- Flange and Exhaust Expanders

- Mufflers

LUBE SYSTEM

- Oil Pan

- Oil Pan Accessories

- Sump Pumps

- Lubricating Oil

PROTECTION SYSTEM

- Air Inlet Shutoffs

- Switches and Contactors

- Explosion Relief Valve

- Sensors

SPECIAL APPEARANCE

- Special Appearance Packages with Chrome Covers

- Chrome Plated Relief Valves

- Black Air Cleaners

- Yacht Class Finish

STARTING SYSTEM

- Starting Motors or Barring Device

- Air Starting Motor Options:

- Starting Aids

- Battery Sets – 24 Volt – Dry

- Battery rack

GENERAL

- Tool set

- Caterpillar datalink wire

PACKING

- Shrink Wrap Protection

- Storage Preservation with Glycol Solution/Vapor Corrosion Inhibitor

- Storage Preservation with Vapor Corrosion Inhibitor

- Export Packaging